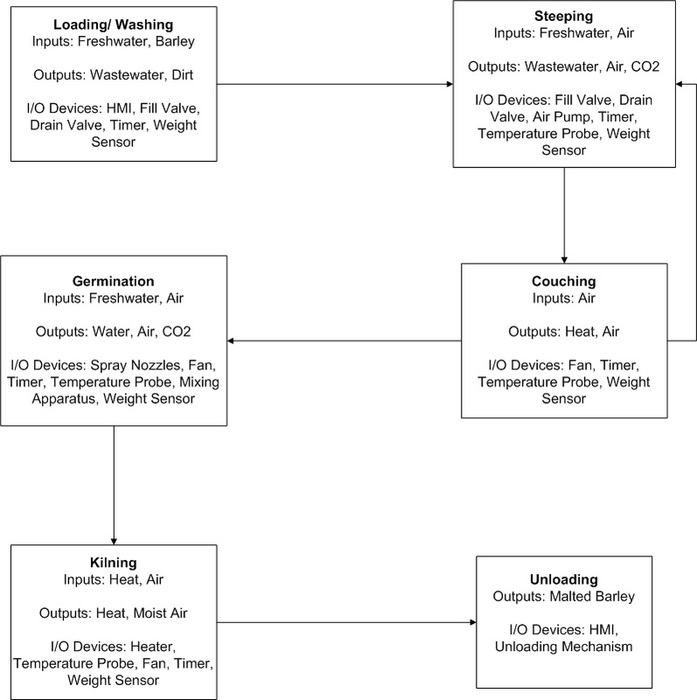

Malting Process

The malting process can be divided into three distinct phases; steeping, germination, and kilning. Also prior to steeping a rinse of the grain will be needed to get rid of any chaff or small particles.

Steeping

Germination

Kilning

Steeping

Germination

Kilning

Great Western Malting Tour

While at Great Western Malting Co. we talked with John Cuti, who gave us an overview of the malting process and answered some questions. The following information will be divided into the three phases of malting.

Moisture % of the barley prior to steeping will be around 10%. After steeping it will be around 46%. Finally after kilning it should be around 4%.

Steeping

6 hour immersion followed by a 10 hour couch. Barley moisture % after cycle ~38-41%

4 hour immersion followed by a 2 hour final couch. Barley moisture % after cycle ~44-47%

Germination

Kilning

Moisture % of the barley prior to steeping will be around 10%. After steeping it will be around 46%. Finally after kilning it should be around 4%.

Steeping

- The steeping water should be well aerated with a high volume, low pressure stream of air.

- The water should also be cycled with a small percentage overflowing and being replaced by fresh water. This helps clear any "dirt" away.

- CO2 may build up at the bottom of the steeping vessel and so some way to remove it may be necessary. One way is to use the aeration nozzles to push air through the grain bed.

- Don't use any painted surface inside of the steeping vessel as it may chip off. If possible use stainless steel.

- The steeping is done in an immersion/drain cycle. The following would be an example:

6 hour immersion followed by a 10 hour couch. Barley moisture % after cycle ~38-41%

4 hour immersion followed by a 2 hour final couch. Barley moisture % after cycle ~44-47%

- During the couch part of the cycle grain should not rise above 75F, but keeping it below 70F would be best.

- The steeping water temperature can be raised to shorten the steeping cycle, but again the temperature of the grain should not exceed 75F.

- It typically takes 45 minutes to fill the steeping vessel and 45 minutes to drain, but this time is not critical and can be varied.

- Another variation of the steeping cycle can be to use sprinklers/spray nozzles to spray on the grain bed while the bottom of the vessel is free draining. This is different from immersion in that the grains do not sit fully submerged in the water. The cycle would be similar to the example above, but adjusted to make sure grain temperature does not get too high.

Germination

- During germination the depth of the grain bed is not critical and can vary from 6" to 3 feet.

- There should be an adequate amount of airflow through the grain bed during the germination phase. Somewhere on the order of 4 CFM/bushel of barley.

- The grain needs to be damp during germination. This can be accomplished by using humid air to flow through the grain. Or sprinklers/spray nozzles can be used to periodically spray the grain bed with water.

- During the first 24 hours of germination physical abuse on the barley should be minimized. NO turning during this period.

- After the initial 24 hours, turning is done once every 8 hours.

Kilning

- Airflow through the grain during kilning is around 100 CFM/bushel.

- Air temperature should start low, around 130F and then progress up to around 200F depending on malt type desired. The low initial temperature is to make sure enzymes within the malt are not activated while it's still wet.

- Being able to recirculate the hot air would help to create different types of malt.

- The kilning process will produce a lot of dust so make sure there is an easy way to clean. Keep important